In the world of aviation safety, few components are as essential as obstruction lighting. These systems are designed to mark potential hazards—such as tall buildings, communication towers, cranes, and wind turbines—that could pose a risk to aircraft navigation. The performance and reliability of these systems are directly influenced by the quality of the obstruction lights themselves, which is where the role of obstruction light OEM (Original Equipment Manufacturer) comes into play. As the industry continues to grow and evolve, OEMs are at the forefront of designing, producing, and innovating these vital safety components. This article delves into the significance of obstruction light OEMs, their impact on aviation safety, and the future of obstruction lighting technology.

The Importance of Obstruction Lighting in Aviation

Obstruction lighting is crucial for marking structures that could obstruct an aircraft's flight path, particularly in low-visibility conditions, such as at night or in adverse weather. These lights serve as visible signals to pilots, helping to prevent collisions and accidents that could arise from undetected hazards. Properly functioning obstruction lights are vital not only in ensuring air safety but also in complying with international aviation regulations set by bodies like the Federal Aviation Administration (FAA) and the International Civil Aviation Organization (ICAO).

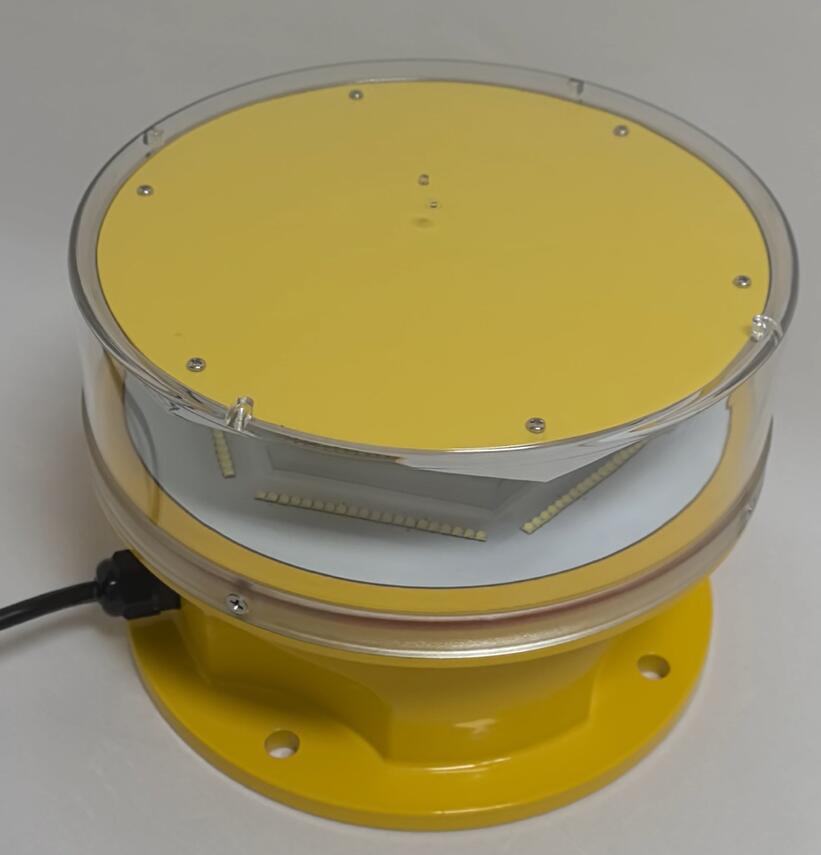

Given the diversity of obstructions—ranging from small towers to massive wind turbines—obstruction lights must be designed for varying environmental conditions and operational requirements. The obstruction light OEM is responsible for producing lights that meet these needs while also adhering to safety standards, technological advancements, and environmental considerations.

The Role of Obstruction Light OEM

An obstruction light OEM is a manufacturer specializing in the production of lights that are designed to mark obstructions in the airspace. OEMs are responsible for the entire lifecycle of the obstruction lights, from design and engineering to manufacturing, testing, and distribution. These manufacturers must work closely with regulatory agencies, engineers, and operators to ensure that their products meet the highest standards of performance and safety.

Some key roles of an obstruction light OEM include:

Design and Engineering

The first step in the process is the design and engineering of the obstruction lights. OEMs must ensure that their products meet a variety of technical specifications, including brightness, flash patterns, color (usually red or white), and the ability to function in harsh environmental conditions, such as extreme temperatures or high winds. The design must also take into account energy efficiency, long lifespan, and low maintenance requirements.

Customization

Different obstructions require different types of lighting. For example, tall buildings and communication towers may require high-intensity lights, while smaller obstructions may only need low-intensity markers. An obstruction light OEM must be able to provide customized solutions based on the specific needs of the installation. This could involve designing lights that meet local regulations, are suitable for specific environmental conditions, or integrate with existing safety systems.

| obstruction light OEM | obstruction lights OEM |

Testing and Quality Assurance

Once the lights are manufactured, OEMs are responsible for conducting rigorous testing to ensure that the lights meet all regulatory standards and function reliably under various conditions. This may involve checking for light intensity, flash patterns, and compliance with FAA or ICAO guidelines. The OEM must also verify that the lights are durable and capable of withstanding external factors such as wind, rain, and snow.

After-Sales Support

The relationship between an obstruction light OEM and their customers extends beyond the sale. OEMs are typically involved in the ongoing support and maintenance of their products, offering troubleshooting, repair services, and parts replacement. This ensures that the obstruction lighting systems remain operational and effective throughout their lifespan.

Technological Advancements by Obstruction Light OEMs

In recent years, obstruction light OEMs have driven significant technological innovations in the field of aviation safety. These advancements are aimed at improving the efficiency, reliability, and environmental sustainability of obstruction lighting systems. Some of the key trends include:

LED Technology

One of the most significant innovations in obstruction lighting is the shift from traditional incandescent bulbs to LED technology. LEDs are more energy-efficient, have a longer lifespan, and are more resistant to environmental factors than older light sources. They also provide more consistent light intensity and are available in various colors and flash patterns, allowing for greater customization based on specific regulatory requirements.

Solar-Powered Solutions

Another major advancement is the development of solar-powered obstruction lights. Solar panels integrated into the lighting systems allow them to operate independently of external power sources, making them ideal for remote locations or areas without easy access to electrical grids. Solar-powered obstruction lights reduce maintenance costs and contribute to more sustainable aviation infrastructure.

Wireless Communication and Monitoring

Modern obstruction light OEMs are increasingly integrating wireless communication features into their products. These lights can be monitored remotely, allowing operators to track their status and performance in real time. If a light fails or is damaged, maintenance teams are immediately alerted, reducing downtime and preventing safety risks. Remote diagnostics and automated monitoring systems are also enhancing the operational efficiency of obstruction lighting systems.

Dimmable and Adaptive Lighting

Dimmable obstruction lights have been developed to adapt their intensity based on ambient light levels. During the day, these lights can be dimmed to reduce light pollution, while at night, they brighten to their full intensity for maximum visibility. This adaptability not only enhances safety but also helps mitigate environmental concerns, particularly in areas with sensitive wildlife or ecosystems.

Challenges Faced by Obstruction Light OEMs

Despite the significant advancements in technology, obstruction light OEMs face several challenges in their operations. One major issue is the need to comply with a wide range of regulatory standards across different regions and countries. Regulations for obstruction lights can vary significantly, requiring OEMs to produce products that are adaptable to different legal requirements.

Another challenge is the increasing demand for environmentally friendly solutions. As the aviation industry and urban development expand, there is a growing emphasis on reducing light pollution and minimizing the environmental impact of obstruction lighting. OEMs must find ways to balance effective visibility with minimal ecological disruption.

Finally, there is the challenge of ensuring the durability and reliability of obstruction lights in the face of extreme weather conditions. OEMs must continually innovate to ensure that their products can withstand the forces of nature, particularly for installations in remote or harsh environments.

The Future of Obstruction Light OEMs

Looking ahead, the role of obstruction light OEMs will continue to be vital in shaping the future of aviation safety. As global air traffic increases and new types of obstructions, such as wind turbines, become more common, the demand for advanced, customized obstruction lighting solutions will only grow. Additionally, as smart cities and drone technology become more widespread, OEMs will need to design lights that are compatible with emerging technologies.

The future of obstruction lighting lies in further advancements in energy efficiency, sustainability, and integration with smart systems. With ongoing innovation from obstruction light OEMs, the aviation industry will continue to evolve toward safer, more efficient, and environmentally conscious air travel.

Obstruction light OEMs are integral to maintaining the safety and efficiency of modern aviation systems. By designing and manufacturing cutting-edge lighting solutions that comply with regulatory standards, integrate new technologies, and promote environmental sustainability, these OEMs play a critical role in reducing the risks associated with airborne collisions. As technology continues to advance, the contributions of obstruction light OEMs will remain at the forefront of aviation safety, ensuring that both air and ground operations are protected from the dangers posed by unmarked obstructions.